In the world of industrial automation and precision metal fabrication, CNC plasma cutting systems have revolutionized how manufacturers achieve high accuracy and efficiency. At the heart of these systems lie critical components such as PlasmaDiv controllers, CNC plasma electronics, stepper motor drivers, and precise stepper motor current regulation. Understanding how these elements work together is essential for optimizing performance, reducing errors, and ensuring long-term reliability in plasma cutting applications.

This article explores each of these key components in depth, answering fundamental questions about their roles, functionalities, and best practices for implementation. Whether you’re an engineer designing a new CNC plasma system or a technician troubleshooting an existing setup, a solid grasp of PlasmaDiv technology, CNC plasma electronics, stepper motor driver selection, and stepper motor current tuning will help you achieve superior results.

By the end of this guide, you’ll have a clearer understanding of how these technologies integrate within a CNC plasma system, ensuring smooth operation, precision cuts, and maximum energy efficiency. Let’s dive into the core components that make modern plasma cutting systems so powerful.

What Is PlasmaDiv and How Does It Enhance CNC Plasma Cutting?

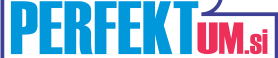

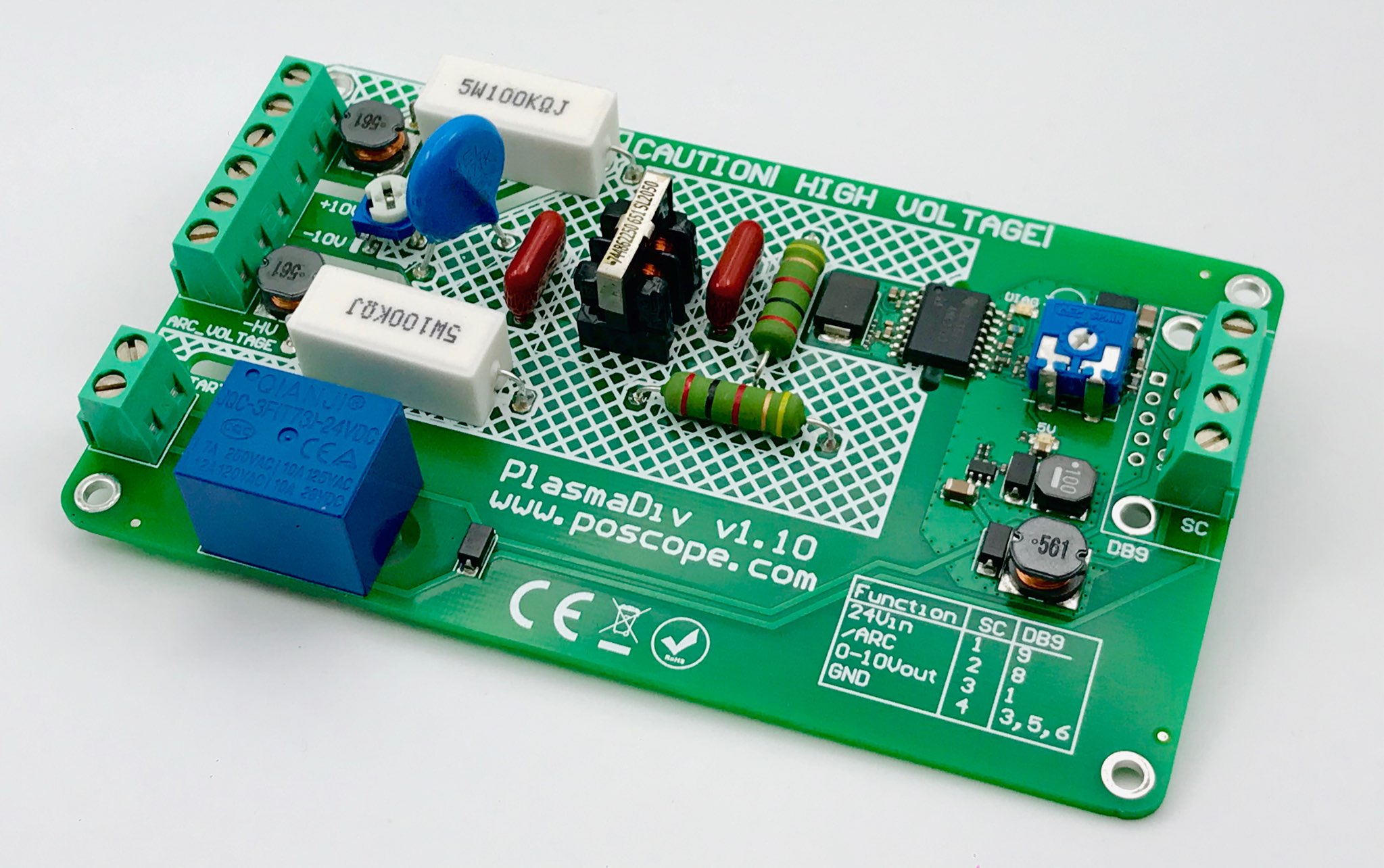

CNC plasma cutting systems depend on advanced control mechanisms to achieve precision, speed, and reliability. At the core of these systems lies PlasmaDiv, a specialized control module designed to optimize plasma torch performance. But what exactly is PlasmaDiv, and how does it elevate the capabilities of CNC plasma cutting?

The Role of PlasmaDiv in CNC Plasma Systems

PlasmaDiv serves as an intelligent electronic control unit that manages essential plasma torch functions, including ignition, arc stability, and shutdown sequences. It acts as a critical link between the CNC plasma electronics, such as the motion controller, and the plasma power supply, ensuring seamless communication and real-time adjustments.

Unlike basic plasma control modules, PlasmaDiv incorporates advanced features for superior performance. It continuously monitors voltage and adjusts cutting parameters dynamically based on material thickness, ensuring consistent results. The system also optimizes the pilot arc for reliable torch ignition, even when consumables are worn. Additionally, PlasmaDiv detects errors such as gas pressure faults or unstable arcs, allowing for quick troubleshooting and minimizing downtime.

By integrating PlasmaDiv into a CNC plasma system, operators experience smoother cuts, reduced dross formation, and longer-lasting consumables.

Integration with CNC Plasma Electronics

A CNC plasma system is a complex network of components working in unison. The motion controller directs machine movement through stepper motor drivers, while the plasma power supply generates the high-energy arc required for cutting. The height control system maintains the correct torch-to-workpiece distance throughout the operation.

PlasmaDiv plays a pivotal role in synchronizing these elements. It interprets signals from the CNC plasma electronics and translates them into precise commands for the plasma torch. For instance, when the CNC controller initiates a cut, PlasmaDiv ensures the arc starts with the correct current ramp-up. If the stepper motor driver accelerates the torch movement, PlasmaDiv adjusts the plasma output to prevent arc lag, maintaining cut quality even at high speeds.

Key Benefits of Using PlasmaDiv

The advantages of incorporating PlasmaDiv into a CNC plasma system are significant. It enhances cut quality by stabilizing arc voltage and current, reducing issues like beveling and inconsistent kerf width. The system’s automated fault detection prevents costly errors, such as misfires or torch collisions, improving overall process reliability.

Energy efficiency is another major benefit, as PlasmaDiv optimizes power delivery to minimize waste, lowering operational costs. Its compatibility with modern CNC plasma electronics and stepper motor drivers ensures seamless integration, allowing for perfectly synchronized motion and plasma output.

Industrial Applications of PlasmaDiv

PlasmaDiv is widely utilized in industries that demand high-precision plasma cutting. In metal fabrication, it enables the creation of intricate shapes in materials like steel, aluminum, and stainless steel. The automotive manufacturing sector relies on PlasmaDiv for cutting chassis components and exhaust systems with exceptional accuracy.

Shipbuilding is another field where PlasmaDiv proves invaluable, as it delivers stable, high-power plasma arcs capable of handling thick metal plates. Across all these applications, PlasmaDiv ensures that the stepper motor current and plasma arc remain perfectly aligned, eliminating problems like jerky motion or uneven cuts.

The Importance of PlasmaDiv in Modern CNC Plasma Systems

PlasmaDiv is far more than a simple control module—it is a vital component that boosts the efficiency, precision, and reliability of CNC plasma cutting. By working in concert with CNC plasma electronics, stepper motor drivers, and stepper motor current regulation, it delivers optimal performance across a wide range of industrial applications.

For businesses seeking to maximize their plasma cutting capabilities, investing in a system equipped with PlasmaDiv technology can lead to greater productivity, less material waste, and superior cut quality. The next chapter will delve deeper into CNC plasma electronics, exploring how these systems process commands and execute precise cuts with unmatched accuracy.

How Do CNC Plasma Electronics Enable Precision Cutting?

At the heart of every high-performance plasma cutting system lies sophisticated CNC plasma electronics that transform digital designs into perfectly executed cuts. These electronic systems serve as the brain of the operation, coordinating motion control, power delivery, and cutting parameters with remarkable precision. But what exactly makes these electronics so crucial for modern plasma cutting applications?

The Core Components of CNC Plasma Electronics

Modern CNC plasma electronics consist of several interconnected systems working in perfect harmony. The motion controller stands as the central processing unit, interpreting G-code instructions and translating them into precise movement commands. This controller works in tandem with stepper motor drivers that convert electrical signals into mechanical motion, ensuring the plasma torch follows the programmed path with micron-level accuracy.

The power supply regulation system represents another critical element, working closely with components like PlasmaDiv to maintain optimal cutting energy. Advanced voltage and current monitoring circuits constantly adjust parameters to compensate for material variations, while height control systems use precision sensors to maintain the ideal torch-to-workpiece distance throughout each cut.

Precision Control Through Advanced Electronics

What sets modern CNC plasma electronics apart is their ability to make real-time adjustments during the cutting process. As the torch moves across the workpiece, the system continuously monitors arc characteristics through sophisticated feedback loops. When cutting thicker materials, the electronics automatically increase current output while coordinating with the stepper motor current regulation to maintain smooth motion.

The integration of high-speed processors allows these systems to execute complex cutting paths without sacrificing speed or accuracy. This becomes particularly important when processing intricate designs where sharp corners and tight curves demand perfect synchronization between the plasma arc and mechanical movement. The electronics ensure the torch never outruns the plasma arc or lags behind commanded positions.

Communication Protocols and System Integration

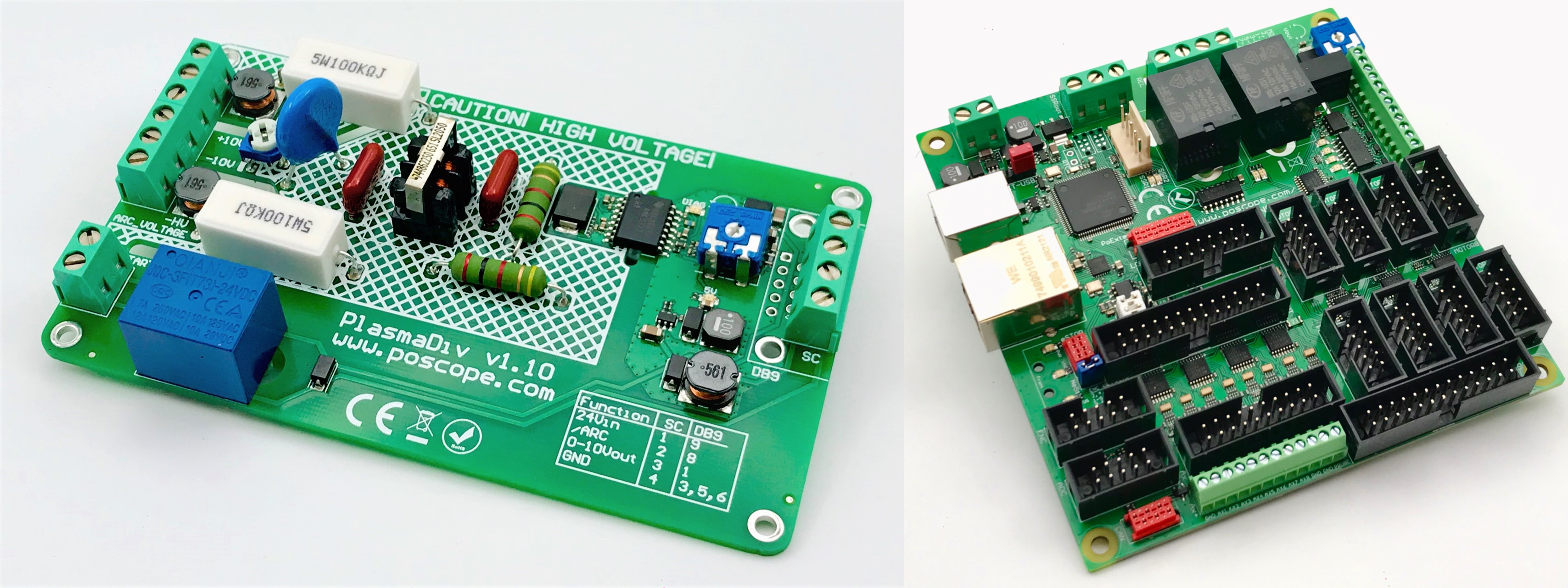

Effective CNC plasma electronics rely on robust communication networks to coordinate all system components. Modern systems typically use high-speed Ethernet or specialized industrial protocols to exchange data between the controller, stepper motor drivers, and plasma power supplies. This networked approach allows for centralized monitoring and control while maintaining the tight timing requirements of precision cutting.

The electronics also interface with various sensors throughout the system, including arc voltage monitors, height sensors, and temperature probes. This constant stream of feedback enables the system to make micro-adjustments to cutting parameters, ensuring consistent quality even when working with imperfect materials or challenging environmental conditions.

The Impact on Cutting Performance and Quality

The sophistication of today’s CNC plasma electronics directly translates to measurable improvements in cutting performance. Operators benefit from cleaner cuts with minimal dross, tighter tolerances, and reduced thermal distortion of workpieces. The ability to store and recall cutting parameters for different materials and thicknesses significantly reduces setup time between jobs.

Advanced features like dynamic power adjustment and predictive maintenance monitoring further enhance system capabilities. The electronics can detect subtle changes in performance that indicate worn consumables or other potential issues, alerting operators before quality is compromised. This level of intelligence, combined with precise stepper motor current control, represents the cutting edge of plasma cutting technology.

Future Developments in Plasma Cutting Electronics

As CNC plasma electronics continue to evolve, we’re seeing the integration of artificial intelligence and machine learning algorithms. These advancements promise even greater automation, with systems that can automatically optimize cutting parameters based on material analysis and desired outcomes. The ongoing miniaturization of components allows for more compact control systems without sacrificing capability, while improved networking enables better integration with factory-wide automation systems.

The next generation of plasma cutting electronics will likely feature enhanced connectivity for remote monitoring and control, along with more sophisticated diagnostic capabilities. These improvements, combined with ongoing refinements in stepper motor driver technology and power regulation, will continue pushing the boundaries of what’s possible in precision plasma cutting.

How Do Stepper Motor Drivers Impact CNC Plasma Cutting Performance?

In the precise world of CNC plasma cutting, stepper motor drivers serve as the critical link between electronic commands and physical movement. These specialized components convert low-power control signals into the powerful electrical pulses that drive stepper motors, ultimately determining the accuracy and reliability of the entire cutting system. But what makes high-quality stepper motor drivers so essential for optimal plasma cutting performance?

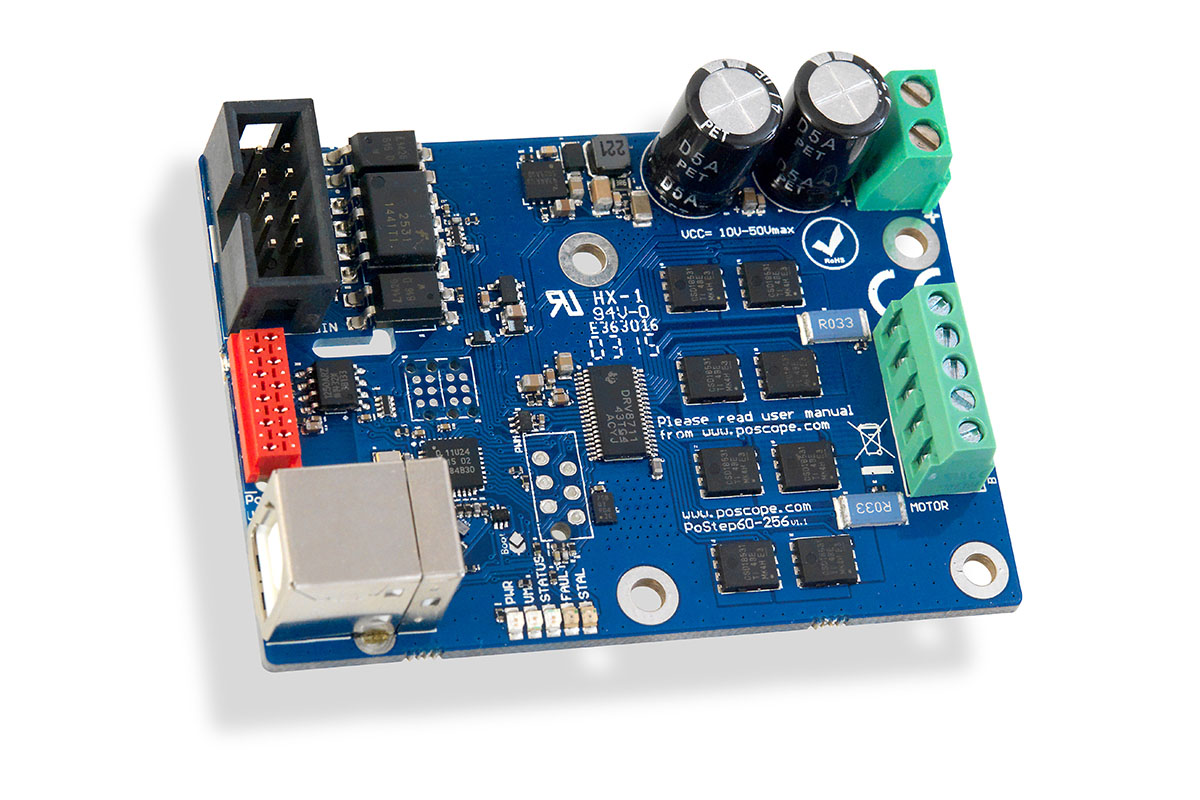

The Fundamental Role of Stepper Motor Drivers

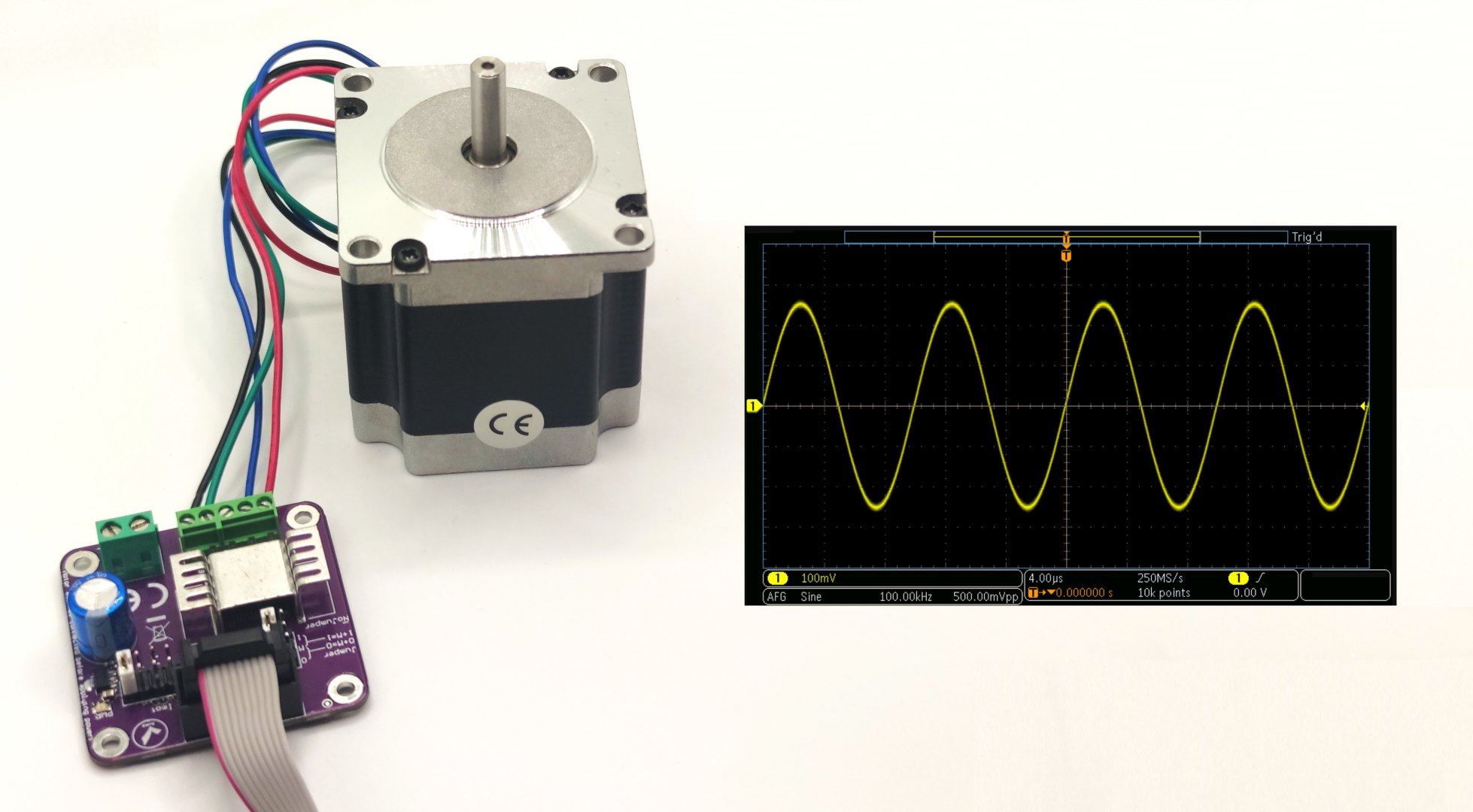

Stepper motor drivers function as sophisticated power amplifiers that precisely control the movement of CNC axes. Unlike simple on/off switches, these drivers use microstepping technology to divide each motor step into smaller increments, enabling smoother motion and higher positioning accuracy. In a plasma cutting system, this translates to cleaner cuts with sharper details and minimal vibration.

The relationship between stepper motor drivers and stepper motor current regulation is particularly crucial. Quality drivers implement advanced current control algorithms that maintain optimal torque while minimizing heat generation. This becomes especially important during long cutting operations where consistent performance is required across extended periods. Modern drivers can automatically adjust the stepper motor current based on real-time load conditions, preventing missed steps while optimizing energy efficiency.

Key Performance Characteristics of Plasma Cutting Drivers

High-performance stepper motor drivers for CNC plasma applications must meet several demanding requirements. They need to handle rapid acceleration and deceleration without losing position accuracy, a capability that directly affects the system’s ability to maintain cut quality during direction changes. The best drivers feature sophisticated anti-resonance technology that prevents vibration at certain speeds, ensuring smooth motion throughout the entire operating range.

Another critical aspect is the driver’s ability to maintain precise control over stepper motor current under varying loads. As a plasma torch encounters different cutting resistances, the mechanical load on the motors fluctuates. Advanced drivers compensate for these variations by dynamically adjusting current output, preventing the stuttering or hesitation that can lead to imperfect cuts. This dynamic response capability separates industrial-grade drivers from their more basic counterparts.

Integration with CNC Plasma Control Systems

Modern stepper motor drivers don’t operate in isolation—they’re integral components of the complete CNC plasma electronics ecosystem. Through sophisticated communication interfaces, they receive motion commands from the central controller while providing real-time feedback about motor performance. This bidirectional data flow allows for closed-loop control strategies that can detect and correct positioning errors before they affect cut quality.

The synchronization between stepper motor drivers and the plasma power source is particularly critical. During complex cutting patterns, the drivers must coordinate precisely with the PlasmaDiv control system to ensure the plasma arc remains perfectly positioned relative to the moving torch. Any timing discrepancy can result in arc lag or lead, causing defects in the finished cut. High-end drivers achieve this synchronization through precise pulse timing and advanced motion profiling algorithms.

Technical Advancements in Driver Technology

The latest generation of stepper motor drivers incorporates several technological innovations that benefit plasma cutting applications. Many now feature advanced digital signal processors (DSPs) that enable more sophisticated control algorithms than traditional analog drivers. These digital drivers can implement complex acceleration profiles, automatic resonance damping, and adaptive stepper motor current control—all contributing to smoother, more precise motion.

Another significant development is the integration of networking capabilities. Ethernet-enabled drivers can receive commands and report status over industrial networks, simplifying system wiring and enabling more sophisticated diagnostics. Some cutting-edge drivers even incorporate machine learning algorithms that analyze usage patterns to optimize performance over time, automatically adjusting parameters like stepper motor current and microstepping resolution for different cutting scenarios.

Selecting the Right Driver for Plasma Cutting Applications

Choosing appropriate stepper motor drivers requires careful consideration of several factors. The current rating must match the motors’ requirements while providing sufficient headroom for peak demands. Voltage compatibility is equally important, as insufficient voltage can limit high-speed performance. Many professionals recommend selecting drivers with at least 20-30% more capacity than the nominal motor ratings to ensure reliable operation under all conditions.

The driver’s microstepping resolution significantly affects motion smoothness and positioning accuracy. While basic drivers might offer full- or half-step operation, premium models provide up to 256 microsteps per full step—dramatically reducing vibration and improving cut quality. However, higher microstepping levels require more precise stepper motor current control, making driver quality even more critical at these fine resolutions.

The Future of Motion Control in Plasma Cutting

As CNC plasma technology continues advancing, stepper motor drivers are evolving to meet new challenges. Emerging technologies like closed-loop stepper systems combine the precision of traditional steppers with the reliability of servo systems, potentially offering the best of both worlds. These hybrid systems use encoder feedback to verify position while maintaining the simplicity and cost-effectiveness of stepper motor designs.

Another promising development is the integration of smart diagnostic features directly into stepper motor drivers. Future systems may be able to predict motor maintenance needs by analyzing current signatures and performance trends over time. Combined with ongoing improvements in stepper motor current regulation and thermal management, these advancements will continue pushing the boundaries of speed, precision, and reliability in plasma cutting applications.

Why is Stepper Motor Current Critical for CNC Plasma Cutting Accuracy?

The precision of CNC plasma cutting hinges on one often-overlooked factor: stepper motor current regulation. This electrical parameter directly determines motor torque, positioning accuracy, and overall system reliability. But what makes proper stepper motor current control so vital for achieving clean, precise plasma cuts?

The Physics Behind Stepper Motor Current

Stepper motor current represents the lifeblood of motion control in CNC plasma systems. Unlike voltage, which determines speed potential, current directly influences the magnetic field strength that generates motor torque. Each microstep of movement requires precise current modulation through the motor windings, with the stepper motor driver acting as a sophisticated current regulator.

In plasma cutting applications, the relationship between stepper motor current and cutting force is particularly crucial. As the torch encounters varying resistance when cutting different materials and thicknesses, the motors must maintain consistent torque output. Too little current results in lost steps and positional errors, while excessive current generates unnecessary heat that can degrade motor performance and lifespan.

Current Control Techniques in Modern Systems

Advanced stepper motor drivers employ several innovative methods to optimize stepper motor current:

Microstepping current modulation dynamically adjusts current levels between microsteps for smoother motion. Rather than applying full current continuously, the driver calculates optimal levels for each position, reducing vibration and improving cut quality.

Adaptive current scaling automatically reduces holding current when the motor is stationary, then ramps up precisely when motion begins. This technique significantly decreases energy consumption and heat generation without sacrificing responsiveness.

Closed-loop current monitoring uses sensitive feedback circuits to detect actual current flow versus commanded values. This allows for real-time compensation of electrical resistance changes caused by temperature fluctuations in the motor windings.

Impact on Cutting Quality and System Performance

Proper stepper motor current regulation manifests in several measurable performance benefits:

Enhanced Edge Quality – Precise current control eliminates the micro-vibrations that cause “ripple” effects on cut edges, especially noticeable in thin materials.

Improved Cornering Accuracy – Maintaining optimal current during acceleration/deceleration prevents the rounding of sharp corners that occurs with inferior current regulation.

Extended Component Life – Correct current levels prevent the excessive heat buildup that degrades motors, drivers, and mechanical components over time.

Energy Efficiency – Smart current management can reduce power consumption by 20-30% compared to fixed-current systems, with no loss of cutting performance.

Unlocking the Secrets of Precision Plasma Cutting: A Guide to Torch Height Control

Troubleshooting Current-Related Issues

Common stepper motor current problems in plasma cutting systems include:

- Choppy motion often indicates insufficient current during acceleration phases

- Positional drift suggests current regulation instability in the driver

- Excessive motor heating typically points to current levels set too high

- Inconsistent cut quality may reveal current fluctuations under varying loads

Diagnosing these issues requires measuring actual current with a true-RMS clamp meter during operation and comparing to driver specifications. Many modern CNC plasma electronics packages include diagnostic tools for monitoring current performance in real-time.

Advanced Current Optimization Techniques

Cutting-edge plasma systems implement several sophisticated stepper motor current optimization strategies:

Load-adaptive current control uses torque demand algorithms to adjust current based on actual cutting resistance. This is particularly valuable when processing mixed materials or variable thickness workpieces.

Predictive current shaping anticipates current needs based on the upcoming motion profile, pre-emptively adjusting levels before each move begins. This technique virtually eliminates lag during rapid direction changes.

Thermal compensation algorithms automatically modify current parameters based on real-time motor temperature feedback, maintaining consistent torque output regardless of operating conditions.

Future Directions in Current Control Technology

Emerging innovations in stepper motor current regulation include:

- AI-driven current optimization that learns from cutting patterns

- Ultra-high-frequency PWM switching for finer current control

- Integrated current/temperature/vibration sensing in smart motors

- Wireless current monitoring for improved maintenance diagnostics

These advancements promise to push plasma cutting precision to new levels while further reducing energy consumption and maintenance requirements. As CNC plasma electronics continue evolving, stepper motor current control remains a critical frontier for performance improvement.

Automating the Future: CNC Controllers, PoKeys57U, and the Technologies Behind Reliable Systems

Revolutionizing DIY Projects with PoKeys57U: A Guide to Building Your Own Orchidarium, Cutting Flat Cables, and Mastering Motor Position Control

The Synergy of Precision in CNC Plasma Cutting Systems

The journey through these essential components reveals how PlasmaDiv, CNC plasma electronics, stepper motor drivers, and stepper motor current collectively form the backbone of modern plasma cutting technology. Each element plays a distinct yet interconnected role in achieving the remarkable precision and efficiency that today’s industrial applications demand.

PlasmaDiv emerges as the intelligent orchestrator of plasma arc management, ensuring consistent cutting performance across varying material conditions. Its ability to communicate seamlessly with CNC plasma electronics creates a responsive system that adjusts in real-time to maintain optimal cut quality. The sophisticated electronics, in turn, demonstrate how digital precision transforms design files into flawless physical cuts through careful coordination of all system components.

The critical role of stepper motor drivers highlights the importance of motion control in plasma cutting applications. These devices bridge the gap between electronic commands and mechanical movement, with their performance directly influencing the machine’s ability to execute complex cutting paths accurately. Their evolving technology continues to push the boundaries of what’s possible in high-speed precision cutting.

Perhaps most fundamentally, the discussion of stepper motor current reveals how electrical precision translates to mechanical accuracy. The careful regulation of current flow determines not just motor performance, but ultimately affects cut quality, energy efficiency, and system longevity. This often-overlooked parameter proves to be a cornerstone of reliable operation.

Looking forward, the integration of these technologies promises even greater advancements. We’re moving toward systems where PlasmaDiv controllers communicate more intuitively with CNC plasma electronics, where stepper motor drivers incorporate more sophisticated predictive algorithms, and where stepper motor current regulation becomes increasingly adaptive to real-time conditions. The incorporation of AI and machine learning suggests a future where plasma cutting systems can self-optimize based on material analysis and historical performance data.

For operators and manufacturers, understanding these interconnected systems provides valuable insight for troubleshooting, optimization, and technology selection. The difference between adequate and exceptional cutting performance often lies in how well these components work together. As the technology continues to evolve, those who grasp these fundamental relationships will be best positioned to leverage new capabilities and maintain a competitive edge in precision metal fabrication.